In today’s complex business environment, analyzing supply chain flows is essential for organizations to remain competitive and optimize their operations. Understanding the basics of supply chain flows is the first step towards gaining insights into the efficiency and effectiveness of these crucial processes.

Understanding the Basics of Supply Chain Flows

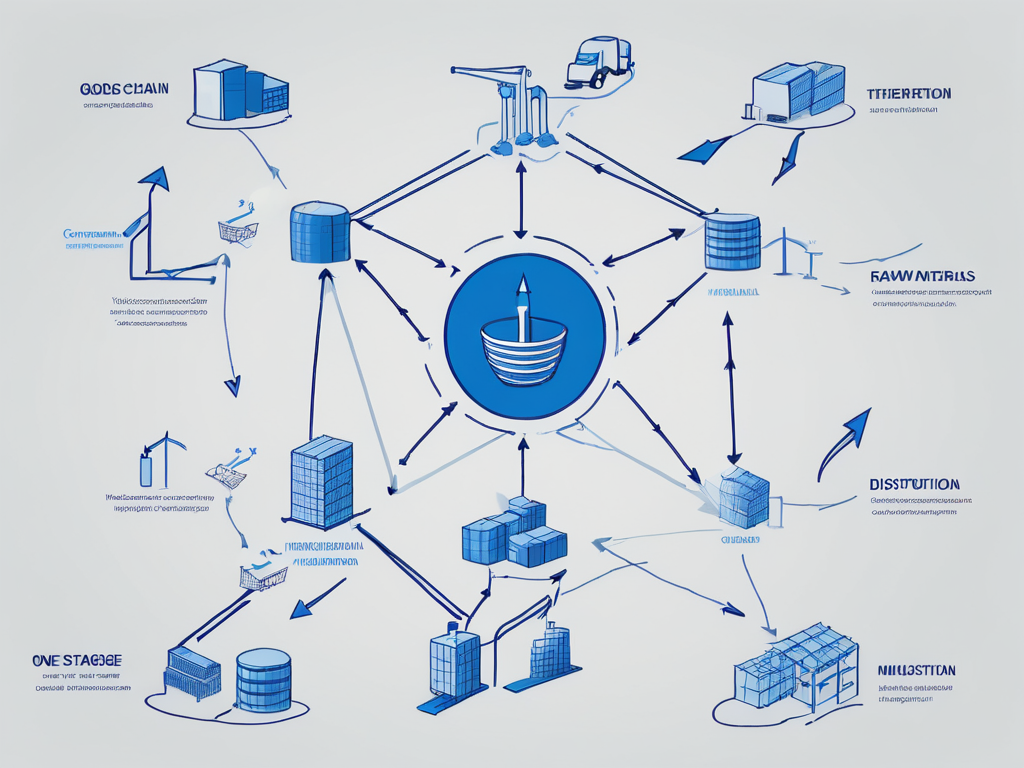

Supply chain flows refer to the movement of goods, information, and cash between different entities within a supply chain network. These flows are interconnected and require careful analysis to identify bottlenecks, inefficiencies, and opportunities for improvement.

Let’s dive deeper into each component of supply chain flows to gain a better understanding of their significance.

Defining Supply Chain Flows

Supply chain flows can be broadly categorized into three key components:

- Product Flow: This involves the physical movement of goods from suppliers to manufacturers, and from manufacturers to distributors, retailers, and ultimately to the end customers.

- Information Flow: Information is the lifeblood of supply chain operations. It includes data on orders, inventory levels, production schedules, and customer demand. Accurate and timely information flow enables organizations to make informed decisions and respond quickly to market changes.

- Cash Flow: Money flows through the supply chain as payments are made for goods and services. Efficient cash flow management is crucial for maintaining financial stability and ensuring smooth operations.

These three components work in harmony to ensure the seamless functioning of the supply chain, enabling products to reach customers efficiently and effectively.

Importance of Supply Chain Flows in Business

Effective supply chain flows are critical for businesses to meet customer demands, reduce costs, and achieve operational excellence. By analyzing and optimizing supply chain flows, organizations can:

- Improve customer satisfaction by ensuring timely delivery of products and services. When supply chain flows are optimized, customers receive their orders promptly, leading to increased satisfaction and loyalty.

- Reduce inventory holding costs and improve cash flow by minimizing stock levels while maintaining adequate supply. By streamlining the product flow and implementing efficient inventory management practices, organizations can reduce the costs associated with excess inventory and free up cash for other business needs.

- Enhance operational efficiency by identifying and eliminating bottlenecks and inefficiencies in the flow of goods and information. Through continuous analysis and improvement, organizations can identify areas where the supply chain flow can be optimized, leading to streamlined operations and improved productivity.

- Optimize supplier relationships and ensure a reliable and robust supply of materials and components. By establishing strong partnerships with suppliers and maintaining open lines of communication, organizations can ensure a steady supply of high-quality materials, reducing the risk of disruptions in the product flow.

As businesses strive to stay competitive in today’s dynamic marketplace, understanding and optimizing supply chain flows is crucial. By focusing on the seamless movement of goods, information, and cash, organizations can achieve greater efficiency, cost savings, and customer satisfaction.

Components of Supply Chain Flows

Now that we have a solid understanding of the basics, let’s dive deeper into the components of supply chain flows.

Supply chain flows are complex and multifaceted, involving various aspects that contribute to the smooth functioning of the overall process. In addition to the product flow, which encompasses the physical movement of goods, there are two other crucial components that play a significant role in ensuring the efficiency and effectiveness of the supply chain: information flow and cash flow.

Product Flow

The product flow involves the physical movement of goods along the supply chain. It starts with raw materials being sourced from suppliers and ends with finished products reaching customers. Key considerations in analyzing product flow include:

- Lead time: The time taken for a product to move through the supply chain from procurement to delivery.

- Transportation modes and routes: The most efficient and cost-effective methods for transporting products.

- Inventory management: Balancing inventory levels to meet customer demand while minimizing carrying costs.

Information Flow

Information flow is the backbone of supply chain operations. It enables real-time visibility into inventory levels, demand patterns, production schedules, and other critical data. Without a robust information flow, supply chain management would be plagued with inefficiencies and uncertainties. Key factors to consider when analyzing information flow include:

- Data accuracy and timeliness: Ensuring the information being shared across the supply chain is accurate, up-to-date, and easily accessible to all relevant stakeholders. This ensures that decisions are based on reliable information, leading to better outcomes.

- Technology utilization: The use of advanced technologies like ERP systems, IoT sensors, and data analytics tools to streamline information flow and improve decision-making. These technologies enable real-time data collection, analysis, and sharing, enhancing the overall efficiency of the supply chain.

- Collaboration and communication: Effective collaboration between different entities in the supply chain network is essential for facilitating information sharing and coordination. Clear and open lines of communication ensure that everyone involved is on the same page, leading to smoother operations and better outcomes.

Cash Flow

While product and information flow are vital components of the supply chain, cash flow is equally important from a financial perspective. Efficient management of cash flow ensures the financial stability and sustainability of the supply chain. Key considerations in analyzing cash flow include:

- Payment terms and conditions: Ensuring favorable payment terms with suppliers and customers is crucial for optimizing cash flow. Negotiating terms that align with the cash flow needs of the business can help improve liquidity and financial stability.

- Working capital management: Managing inventory levels and accounts receivable/payable is essential for optimizing cash flow. By carefully balancing these elements, businesses can improve their working capital position and ensure a healthy cash flow.

- Financial forecasting: Accurate forecasting of cash flow is critical to anticipate and address any potential liquidity issues. By analyzing historical data, market trends, and other relevant factors, businesses can make informed decisions and take proactive measures to manage their cash flow effectively.

By understanding and analyzing these three components of supply chain flows – product flow, information flow, and cash flow – businesses can identify areas of improvement and implement strategies to enhance the overall efficiency and effectiveness of their supply chain operations.

Steps to Analyze Supply Chain Flows

Now that we have a comprehensive understanding of supply chain flows, let’s explore the steps involved in analyzing them.

Identifying the Components

The first step is to identify and define the various components of supply chain flows within your organization. This involves mapping out the product flow, information flow, and cash flow and understanding how they interact with each other.

Mapping the Flow

Once the components are identified, the next step is to map the flow of goods, information, and cash through the supply chain. This can be done using flowcharts or process maps, which visually represent the movement and exchange of these components.

Evaluating the Efficiency

After mapping the flow, it’s important to evaluate the efficiency and effectiveness of each component. This involves analyzing key performance indicators (KPIs) such as lead times, cycle times, inventory turnover, and cash-to-cash cycle to identify areas for improvement.

Challenges in Supply Chain Flow Analysis

While supply chain flow analysis is crucial for optimizing operations, it comes with its fair share of challenges. Let’s explore some common challenges organizations face:

Data Collection Issues

Accurate and timely data collection is essential for effective supply chain flow analysis. Often, organizations struggle with data quality, availability, and compatibility across different systems. Implementing robust data collection procedures and investing in integrated IT systems can help mitigate these challenges.

Complex Supply Chain Structures

Supply chains can be complex, with multiple tiers of suppliers, distributors, manufacturers, and customers. Analyzing supply chain flows becomes challenging when dealing with such intricate networks. Advanced analytics tools and supply chain visibility platforms can provide insights into these complexities and help identify inefficiencies.

Changing Market Demands

Market dynamics and customer demands are constantly evolving. Analyzing supply chain flows requires organizations to adapt and respond to these changing demands quickly. Flexibility and agility in operations and supply chain design are vital in meeting customer expectations and remaining competitive.

By following the steps outlined in this comprehensive guide, organizations can gain valuable insights into supply chain flows and identify opportunities for improvement. Analyzing supply chain flows is an ongoing process that requires continuous monitoring and adjustment to keep pace with changing market dynamics. With a well-optimized supply chain, organizations can gain a competitive edge and achieve sustainable growth in today’s dynamic business landscape.

Ready to elevate your supply chain operations and drive profitability for your business? Izba Consulting is here to guide you through every step of the process. With our expertise in helping founders start, scale, and exit their businesses, we focus on enhancing your supply chain to boost cash flow and profitability. Our strategic partnerships and hands-on management approach, backed by a wealth of Fortune 500 and startup experience, make us an invaluable extension of your team. Don’t miss out on the latest insights and strategies for supply chain optimization. Subscribe to our newsletter today and take the first step towards transforming your supply chain into a competitive advantage.