Common E-Commerce Supply Chain Challenges

- Warehouse vs 3PL Fulfillment Options

- Inventory Management (moving, storing, packing, locating, tracking, etc.)

- Ensuring Transparency

- Customer Needs

- Infrastructural Problems (Lack of technology for communication, security, WMS, etc.)

- Uncontrollable Circumstances (Material scarcity, port congestion, difficult demand forecasting, consumer demands, etc.)

How Should E-Commerce Businesses Tackle These Challenges?

- Go for a reliable partnership with a 3PL or hire effective warehouse managers

- Employ cutting-edge software and digital technology to keep and update inventories for clear visibility

- Ensure inventory management (Damage reduction and safe storage)

- Increase profits by affording a reliable delivery partner or ensuring prompt deliveries through own logistics

- Seek consultation (CTA)

E-Commerce Supply Chain Challenges All Businesses Face

E-Commerce Supply Chain

From the moment the materials for a product are collected to its manufacturing and delivery to the end consumer, every stop that’s made in between makes up the supply chain.

The same definition extends to all businesses and industries regardless of their niche and that includes e-commerce as well.

You might think that since most e-commerce businesses aren’t manufacturing their own products, they expect to avoid most of the costs associated with supply chain management. Think again!

Whether it’s the import, warehouse storage or the whole fulfillment process itself, you’ll be accruing costs.

With every supply chain comes problems and challenges that all businesses face as well as the need to design an effective strategy to overcome them.

Common Supply Chain Strategies

Supply chain strategies involve planning how your product is going to go from point A (the manufacturing plant) to point B (end consumer).

Unfortunately, as much as we’d like it to be this simple, the fact remains that points A and B are actually much farther away from each other. Different stops made along the way during the process make it one of the most complicated aspects of running a product-based business.

For example, if an automobile company produces their vehicles in a country, a supply chain strategy for them would entail identifying points where the products will be stored and shipped to/from, the product’s demand forecasts, shipping routes and costs, warehouse capacities and order accuracy, just as examples.

If the company wishes to expand, this would further complicate the model with additional stops and channels that the product will go through.

So far, there are 4 notable supply chain strategies that have proven successful for several businesses in various industries. These include:

- Customer-centricity

- Predictive Maintenance

- Automation

- Visibility

It’s important to note that these supply chain strategies are not the only viable solutions you’ll find to your supply chain challenges. However, to make them work for your business, you’ll need to understand how a supply chain is managed.

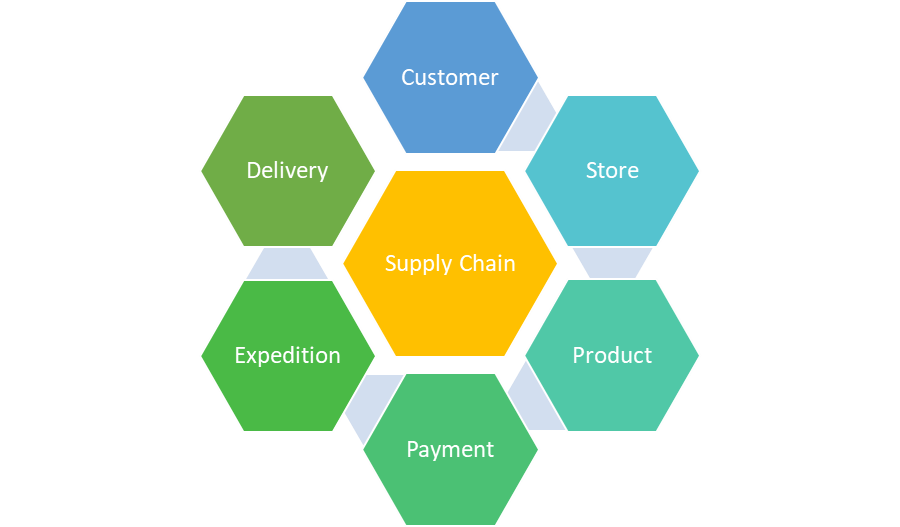

Let’s break down the whole thing into 6 elements:

1. Customer

The end-consumer, an autonomous entity in this whole process upon whose approval and satisfaction it depends, is the most important element of the supply chain. Since they also signify the end of the supply chain, it’s imperative for businesses to bring their products to their customers.

We all know that e-commerce businesses skyrocketed during the pandemic. And we all know that not all of those who endeavored to deliver in time made it.

Thousands of businesses were affected around the world but the ones who survived and made record sales were the ones who optimized their order fulfillment process, i.e. improved their supply chain design.

Inevitably, you’ll have to conform to the demands of the market that are going to be shaped by the customer. Market demand forecasts are as crucial as they are unreliable as many have experienced. Businesses end up wasting a lot of resources and opportunities when it comes to consumer demands.

2. Online Store

The online store where the sale and the order fulfillment process are initiated is not to be taken lightly.

It’s a crucial part of the supply chain process as it serves as a medium of communication between a business and a customer. Ideally, this is a place that should also show the fulfillment process as it takes place but most stores don’t offer this yet.

Not only is the online store your primary source of understanding your target audience, but it’s also going to be helping you predict demand and consumer interests.

3. Product

The product development life cycle involves serious logistical work and not finding resources in time or at the right price can make all the difference.

Geopolitical and economic conditions varying with regions can make things difficult for e-commerce businesses that manufacture their own products.

To curb this, it’s important to understand your product and find alternative options to optimize the development as well as the moving process.

For businesses that offer several products, it’s imperative that you figure out which ones are in demand and which are not. Obviously, in times when moving shipments is hard, you need to prioritize categories and individual products that have better chances of being sold soon.

4. Payment

The payment process is definitely friendlier for businesses now as compared to before. Since payments are required to initiate the process, it’s easier for companies to have revenue forecasts and manage the budget effectively.

While it still doesn’t solve problems like unpredictable demand forecasts or help you figure out how much inventory you need, it certainly helps put things in perspective while generating revenue itself.

5. Expedition

The expedition is the fulfillment process that happens as soon as the payment is made to the online store by the customer for the product. This expedition entails getting the product from its place of manufacture, transporting it to the local retail store or warehouse, and delivering the product to the customer.

Not only is order fulfillment optimization crucial in terms of achieving customer satisfaction, but it also plays a significant role in reducing overall costs accrued in the supply chain.

6. Delivery

Delivery entails ensuring the customer gets what they want. While it may seem simple, things get messy when you look at order picking and fulfillment accuracy for thousands of products. Whether manual errors cause damage or deliveries of wrong products themselves, it ultimately makes the business look bad.

Although it’s the last part of the supply chain, it’s often overlooked as a tiny uncontrollable factor that doesn’t carry much weight. This is where businesses make a mistake because it’s imperative for customers to get the product in order to fulfill the supply chain and ensure you grow your business.

Common E-Commerce Supply Chain Challenges

All e-commerce businesses tend to find themselves facing a series of challenges that involve the following:

1. Warehouse vs 3PL Fulfillment Options

Choosing between your own warehouse and 3rd party logistics and fulfillment centers is one of the first decisions a company has to make.

While a warehouse can serve as a good way to go about doing business locally, you probably won’t have much luck finding a warehouse when you move off-shore. However, regardless of where you choose, your own warehouse means managing it yourself.

Even so, you’ll need to consider going for 3rd party logistics or investing in your own transportation. As the latter seems much more difficult to do, it comes down to choosing the right service provider to partner up with.

This entails getting into service level agreements and comparing order accuracy over time. However, at no point is a business not supposed to be in control of the supply chain.

2. Inventory Management

Managing inventory comes with several different challenges that are being tackled in various manners in every industry. While some are experimenting with FiFo or FiLo inventory management strategies, others are investing in robotics.

Obviously, there is no single solution that can work for every product line in every industry. Having said that, there are significant examples in all industries of how businesses have overcome their inventory management problems.

Since this process entails everything that happens in a warehouse, we need to address the elephant in the room, i.e. traditional warehouse management systems. (Or should we just call them Excel sheets?)

Orthodox reliance on manual inventory management has caused immense damage to companies. Warehouses that don’t have a management system in place are still using printed sheets and inevitably, causing manual errors and facing difficulty in locating inventory.

Another problem with traditional warehouse management is that it doesn’t involve any sort of feedback or visibility.

3. Ensuring Transparency

As explained above, traditional fulfillment operations don’t offer transparency to customers and even client companies. This renders customers and businesses unable to present or address any concerns or issues regarding product deliveries.

Transparency is possible in an FC or a warehouse and it doesn’t have to be limited to just client companies. Not only can warehouse managers and client companies, but you can also present a real-time status report of deliveries to customers awaiting their products.

Time and again, statistics, surveys and customer reviews show that people love knowing as much as possible. Just like how the majority of people tend to move away from shops that don’t list delivery estimates, e-commerce stores that provide real-time visibility tend to have more customer confidence and trust.

4. Customer Needs

Customer demands and needs can change with any event. Depending upon the scale at which you’re operating, you can face tiny delays due to traffic or massive shipment problems due to warring scenarios.

The local contexts entailing economic, geopolitical and social situations can vary with each region you step into. This is also something you should consider when you’re thinking of moving inventories.

It’s obvious that customer needs ultimately affect the most important thing for an eCommerce business, i.e. demand forecasts.

This necessitates a careful and constant evaluation of customer needs and consumer interest. Expert marketers are able to identify and predict hot products that will be needed.

This means that sometimes, you’ll have to rely on information from your sales and operations departments to make crucial business decisions.

Ultimately, the goal is to stay ahead of your target audience in terms of predicting their behavior in order to reduce the chances of wasting opportunities or resources.

5. Infrastructural Problems

Most of the above-listed challenges occur mostly because the right infrastructure isn’t in place for effective supply chain management.

Although a very huge term, infrastructure can refer to technological assets such as digital systems or lack of better, custom software, etc. It can also include improper or insufficient security measures.

Infrastructural issues tend to be critical in nature as even a slight mistake in the whole plan can cause tides of trouble in the future.

When it comes to supply chain design, you need to understand that any and every decision you make right now is going to produce results at least 8-9 months into the future.

This means that any major change you make in your supply chain design is going to be long-term and thus, should be considered seriously. Make sure you employ cutting-edge technology in every area of your business operations to ensure maximum efficiency.

And as for security, don’t just think of your inventory or resources as the only assets you’re protecting. The integrity of your supply chain operations should be the most important thing for a business to protect and for that, you need appropriate security measures in place.

6. Uncontrollable Circumstances

Given the recent circumstances such as the global chip shortage, Russia’s war on Ukraine, port congestion, etc., it’s easy to see how fragile our supply chains can be when faced with global problems.

While it’s true that some of these are unresolvable problems for a business, the rest of them only compel businesses to figure out better ways to manage their supply chains.

Choosing different vendors, finding better and more reliable trade routes, and suppliers that can provide you with materials in place of others, seeking government help, etc. are actions companies are forced to take when the going gets tough.

Another factor that is considered uncontrollable in the contemporary situation is the labor shortage. Since everyone is demanding higher wages, this could be an opportunity for businesses to satisfy labor qualification and competence requirements.

Rather than going for traditional warehouse management, incorporating a digital structure that needs the least amount of labor power to function can be a good way to go about this. Introduce smart digital systems and hire people capable of understanding and handling them.

Since you’ll be cutting costs in the long run, you can offer some of the returns as higher wages to your workers.

How Should E-Commerce Businesses Tackle These Challenges?

There’s not a specific list of problems that need to be overcome by an e-commerce business. Needless to say, all of us have our work cut out for us.

There are suppliers and 3PL vendors to narrow down along with infrastructural improvements that just won’t wait any longer. Your warehouse space needs work and so does your warehouse management system.

The trick to doing all this is designing a supply chain that optimizes fulfillment from the start. Since it’s a long-term problem, you can’t just hope for immediate and instant resolutions. Any serious change can take a substantial amount of time to prove its usefulness.

Established e-commerce businesses that think they’re too far gone to consider massive changes or startups looking to get started the right way should immediately seek consultation from experts at Izba. We’ll help you create a success story that you’ll be proud of in years to come!

2 thoughts on “E-Commerce Supply Chain Challenges All Businesses Face”

Pingback: Choosing A Supply Chain Consultant for Your Business - izba

Pingback: Reefer FTL vs LTL: Which is Better and For Who? - izba