In today’s highly competitive business landscape, having an effective supply plan is essential for success. A well-executed supply plan ensures that your business has the right products, materials, and resources at the right time and at the right cost. It helps streamline operations, minimize costs, and optimize customer satisfaction. In this article, we will guide you through the process of creating an effective supply plan, step by step.

Understanding the Importance of an Effective Supply Plan

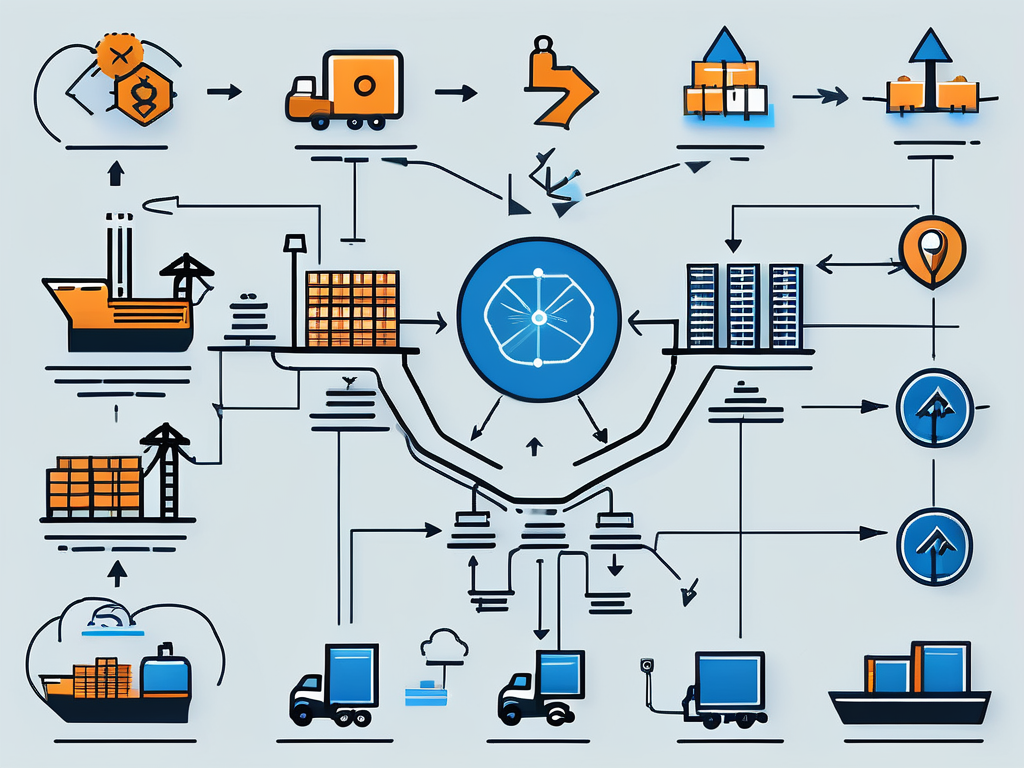

Before delving into the details of creating a supply plan, it’s crucial to understand why it is so important for your business. A supply plan acts as a roadmap that guides your business’s supply chain activities and ensures smooth operations. It helps you anticipate and mitigate potential challenges and risks, such as fluctuations in demand, supply shortages, or unexpected disruptions. By having a clear plan in place, you can effectively manage your inventory, improve customer service, and achieve cost savings.

The Role of Supply Planning in Business

Supply planning plays a vital role in overall business success. It involves analyzing market trends, evaluating current supply chain capabilities, and aligning supply with demand. Effective supply planning enables you to synchronize your production and procurement activities, ensuring that you have the right amount of inventory to meet customer demand. It helps you strike a balance between minimizing costs and maximizing service levels, ultimately driving profitability.

Key Benefits of Effective Supply Planning

An effective supply plan offers several benefits to your business. Firstly, it improves inventory management by reducing excess stock and eliminating shortages. This leads to better cash flow and reduced carrying costs. Secondly, it enhances customer satisfaction by ensuring on-time delivery and minimizing order cancellations or delays. This, in turn, fosters customer loyalty and drives repeat business. Lastly, effective supply planning optimizes resource utilization, reduces waste, and improves overall operational efficiency.

Furthermore, an effective supply plan also enables your business to respond swiftly to market changes and seize new opportunities. By closely monitoring market trends and demand patterns, you can proactively adjust your supply plan to capitalize on emerging trends or address shifts in customer preferences. This agility in supply planning allows your business to stay ahead of the competition and maintain a competitive edge in the market.

In addition, effective supply planning fosters collaboration and communication within your organization and with your suppliers. By involving key stakeholders in the planning process, you can ensure alignment between different departments and functions, facilitating seamless coordination and decision-making. This collaborative approach also strengthens relationships with suppliers, enabling you to negotiate better terms, secure favorable pricing, and establish long-term partnerships based on trust and mutual benefit.

Preliminary Steps for Creating a Supply Plan

Before diving into the detailed process of creating a supply plan, it’s crucial to lay a solid foundation. This involves several preliminary steps that will set you up for success.

Establishing a robust supply plan requires a comprehensive understanding of your business landscape. By delving into the intricacies of your operations, you can better navigate the dynamic market forces and tailor your supply plan accordingly.

Identifying Your Business Needs

Start by assessing your business needs and goals. Understand your target market, customer demands, and growth projections. This will help you develop a supply plan that is aligned with your business objectives.

Conducting a thorough analysis of your business needs involves not only understanding current requirements but also anticipating future trends. By staying ahead of the curve, you can proactively address potential challenges and capitalize on emerging opportunities.

Evaluating Your Current Supply Chain

Analyze your current supply chain capabilities and performance. Identify any bottlenecks, inefficiencies, or areas that require improvement. This evaluation will provide valuable insights into areas that need to be addressed in your supply plan.

Examining the intricacies of your supply chain involves a meticulous review of processes, technologies, and relationships with suppliers. By pinpointing areas for enhancement, you can streamline operations and enhance overall efficiency.

Setting Clear Objectives for Your Supply Plan

Define clear and measurable objectives for your supply plan. These objectives should align with your overall business strategy and address areas such as cost reduction, lead time improvement, inventory optimization, or customer service enhancement. Setting clear objectives will help you stay focused and track your progress.

Establishing precise objectives for your supply plan serves as a roadmap for success. By articulating specific goals, you can align your team’s efforts, monitor performance metrics, and adapt strategies as needed to achieve optimal outcomes.

Detailed Process of Developing a Supply Plan

Once you have completed the preliminary steps, you can move on to the detailed process of creating a supply plan. This process involves various stages that are essential for developing an effective supply plan.

Gathering and Analyzing Relevant Data

Begin by gathering data related to your business operations, such as sales data, historical demand patterns, supplier performance data, and production capacity. Analyze this data to identify trends, patterns, and potential risks that could impact your supply plan. This analysis forms the basis for making informed decisions.

Forecasting Demand and Supply

Use the data gathered and analytical tools to forecast both future demand and supply. Accurate demand forecasting is crucial as it determines the amount of inventory and resources needed. On the other hand, supply forecasting ensures that you can meet the anticipated demand by procuring the necessary materials or products.

Developing a Procurement Strategy

Based on the demand and supply forecasts, develop a procurement strategy. This strategy outlines how you will source raw materials or finished products, negotiate with suppliers, and manage supplier relationships. It also takes into account factors such as cost, quality, and lead time.

Creating a Production Schedule

With the procurement strategy in place, create a detailed production schedule. This schedule specifies what products will be produced, in what quantities, and at what time. It ensures efficient utilization of resources, minimizes bottlenecks, and optimizes production efficiency.

Establishing a Distribution Strategy

Finally, establish a distribution strategy to ensure that your products reach the end customers in a timely and efficient manner. Determine the most appropriate distribution channels, transportation methods, and warehousing solutions based on your business requirements and customer expectations.

Implementing Your Supply Plan

Once your supply plan is developed, it is essential to implement it effectively to reap its benefits.

Communicating the Plan to Relevant Parties

Ensure that all relevant stakeholders within your organization are aware of the supply plan. Clearly communicate the objectives, strategies, and key performance indicators to various teams such as procurement, production, sales, and transportation. Collaboration and alignment among all teams are crucial for successful plan implementation.

Training Staff on the New Supply Plan

Provide adequate training to your staff, especially those directly involved in executing the supply plan. This training should cover topics such as demand forecasting, inventory management, procurement processes, and production scheduling. Equipping your staff with the necessary knowledge and skills will enable them to carry out their responsibilities effectively.

Monitoring the Plan’s Implementation

Regularly monitor and evaluate the implementation of your supply plan. Track key performance indicators, such as on-time delivery, inventory turnover, and order fulfillment rates. Identify any deviations or issues and take timely corrective actions. Continuously review and update your supply plan to adapt to changes in market conditions or business requirements.

By following these step-by-step guidelines, you can create an effective supply plan that aligns with your business objectives and ensures seamless operations. A well-executed supply plan will enhance your competitive edge, improve customer satisfaction, and drive overall business success.

Ready to elevate your business to new heights? Izba Consulting is your go-to partner for starting, scaling, and exiting your business with finesse. Our expertise in enhancing supply chain operations is designed to drive profitability and improve cash flow, ensuring your business thrives in any market condition. Embrace the strategic partnership and day-to-day management that Izba Consulting offers, and watch as we help develop your internal team for sustainable growth. With a unique mix of Fortune 500 and startup experience, our team is equipped to inject innovation and strategic insight into your business. Don’t miss out on valuable insights and updates that can transform your supply chain and business operations. Subscribe to our newsletter today and take the first step towards a more profitable future with Izba Consulting.